Storm and Arc Doors

WHAT YOUR HOME DESERVES

A Family Owned Window and Door Manufacturer You Can Trust.

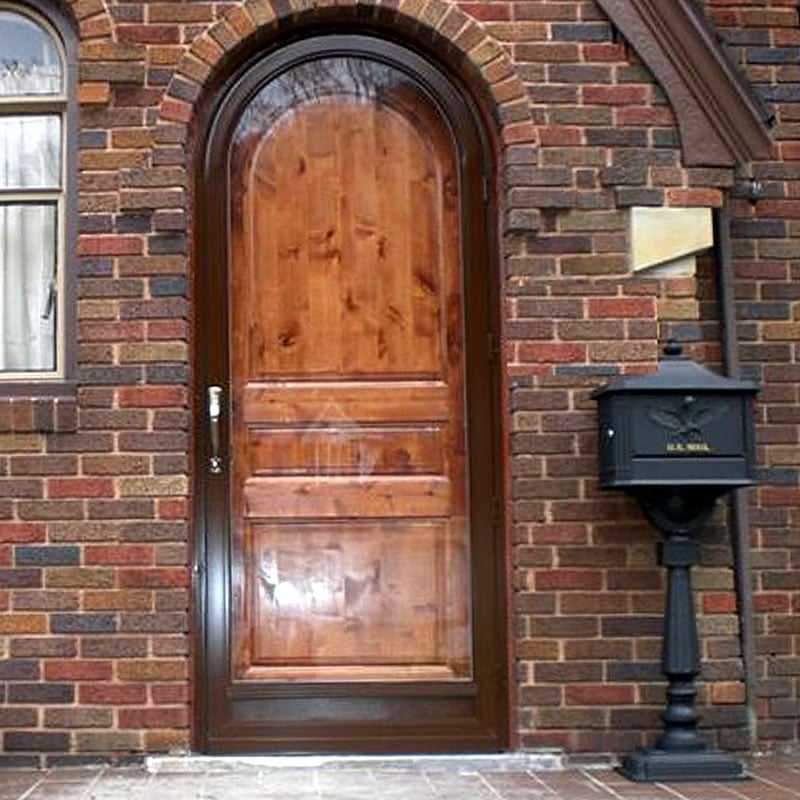

Arch Storm Doors

We Sell & Install Custom Storm and Combination Doors Throughout MA, NH and Maine

Full View:The removable screen and glass panel door has nearly full view interchangeable panels that can be removed and interchanged with the change of seasons. The panels are held in with aluminum color match retainer clips.

Two-Lite:The two-lite has a center bar centered horizontally in the door with a top and bottom interchangeable glass and screen. Both panels are held in with aluminum color match retainer clips. This style is an upgrade from the full view door.

Self-Storing:This type of storm door does not require that the panels be taken out or stored. The top glass is fixed while the bottom inside glass panel moves up as far as the beginning of the arch for ventilation. The bottom outside half screen stays permanent and can be rescreened from the outside. This style is an upgrade from the full view door.

Half View:The half view style is our newest and works well for homes with pets, small children or where enhanced security is desired. This style is manufactured with only the custom top portion having an interchangeable glass and screen. The bottom portion, which can be reinforced either vertically or horizontally, is an all aluminum panel that is separated and reinforced either vertically or horizontally. As an additional upgrade, the bottom panel can also be insulated between a double panel of aluminum but will have the screws securing the two panels visible from the inside and outside of the door. This style is an upgrade from the standard full view door.

Material: The door consists of a hollow extruded master frame and hollow extruded mullion bar, sash and screen inserts and master frame corner gussets manufactured from 6063-T5 extruded aluminum alloy, having a minimum tensile strength of 22,000 PSF. All screws are stainless steel Phillips head. Rolled form aluminum or steel kick plate. General Construction: The hollow master frame of the door is mitered joint construction and joined at the corners by pop rivets driven into the corner gussets through accurately placed holes. The bottom of the door has an aluminum exterior expander channel: 1/8’ from the rearward edge of the bottom face a slot to accept an extruded vinyl plastic or steel door sweep, adjustable to 5/8 of an inch. The kick plate is not less than .030” thick embossed or corrugated aluminum or steel sheet. It is secured to the main frame with weather resisting cement: it also slips into a 3/16” deep groove provided in the main frame and mullion bar for maximum strength and rigidity and to prevent rattling. These hollow mullion bars are accurately machined to fit the frame and are joined to the frame by machine screws for maximum strength. The top surface of the extrusion for center mullion bar is provided with channels to accommodate the inserts.

The extruded glass insert frame is mitered joint construction and secured on all corners by screwing into corner gussets. The glass insert is glazed with Safety Glass (Plexiglass or tempered glass) and set in with marine vinyl glazing. Screening is accomplished by a use of a 16 x 18 fiberglass screen cloth which shall conform to the applicable portion of Federal Specification on RR-W-365 and Amendment 1. Fiberglass cloth is rolled into a groove provided in the extruded frame and is further secured by a vinyl spline. The glass and screen insert frame is held in the door by aluminum clips and #8-32 Rh machine screws. The frame is contained in the mullion bar channel which is an integral part of the main frame. Rivnuts are inserted into the door frame. They are located so the clips and screws do not interfere with the installation of either the door closer or the safety chain. The clips are employed to insure positive contact between the inserts and the master frame and to stop passage of inserts and prevent rattling.

The master frame has a width across the flat surface of the face of not less than 2” and a thickness of not less than 1”. The mullion bars have a width across the flat surface of the face of not less than 1”. All master frame and mullion bar wall thickness has a mean of .045. The extruded aluminum glass insert frame has a dimension of not less than 3/8 of an inch thick, 3/4 of an inch wide. The extruded aluminum screen insert frame has a dimension of not less than 5/16 of an inch thick, 3/4 of an inch wide. The insert frames are manufactured to have a maximum overall clearance of 1/8” in width and 1/8” in height, and to be interchangeable in all doors of the same nominal size and make supplied. All master frame dimensions are permitted a manufacturing tolerance of plus or minus 1/16”. Extrusion tolerance shall be in accordance with those set down by the Aluminum Extruded Products Divisions of the Aluminum Association. The Z-Bar side flange widths are for bearing against the door buck of not less than 1”. Z-Bar return offset on the inside face of 1-3/16”. Z-Bar hinge section will have a continuous hinge (piano hinge) the length of the Z-Bar. The head and side Z-Bar is designed to receive a wool pile weather-stripping for maximum seal against air and dust infiltration. The head Z-Bar is also designed and extruded as to function as a drip cap over top of door. The hardware shall include all necessary stainless steel Phillips head screws, adjustable door closer, the hurricane type chain with hold-up spring, push button type latch with anti-lockout feature.

Installation shall be made in accordance with the manufacturer’s instructions. The unit shall be mounted to the door frame with required operating clearance.